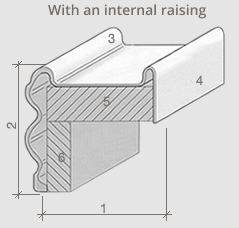

We receive pewter in ingots that we melt in a boiler. We pour it in a mold that we put in shape over a wood frame (CP 30mm or 2x18mm).

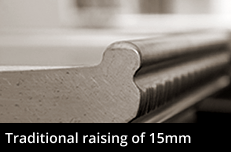

For the edge profiles, we pour pewter in vintage steel molds (1870-1930) for the majority, we also have more contemporary and modern creations.

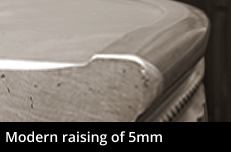

For the edge profiles, we pour pewter in vintage steel molds (1870-1930) for the majority, we also have more contemporary and modern creations.

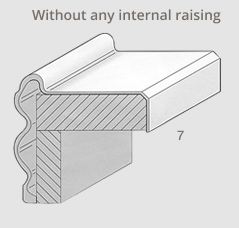

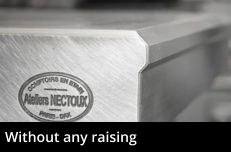

Plates and Edge Profiles are then welded together then grated, filed, shaved in a handcrafted and traditional way.

Our pewter is compliant with EEC and US food hygiene standards.